rubber impeller for slurry pump factories

Latest articles

These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreBCT Ceramic Slurry Pumps

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreCorrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreSlurry Pump

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreA target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read MoreSelecting a dredge pump

rubber impeller for slurry pump factories...

rubber impeller for slurry pump factories 【rubber impeller for slurry pump factories】

Read More

Popular articles

- method and level of design reach international advanced level. The company has the first-class pump performance

- Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

- Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

- Rubber Lined Slurry Pump

- Pumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

Latest articles

-

Mechanical Seals

-

>Slurry Pump

-

how-does-a-dredge-pump-work

-

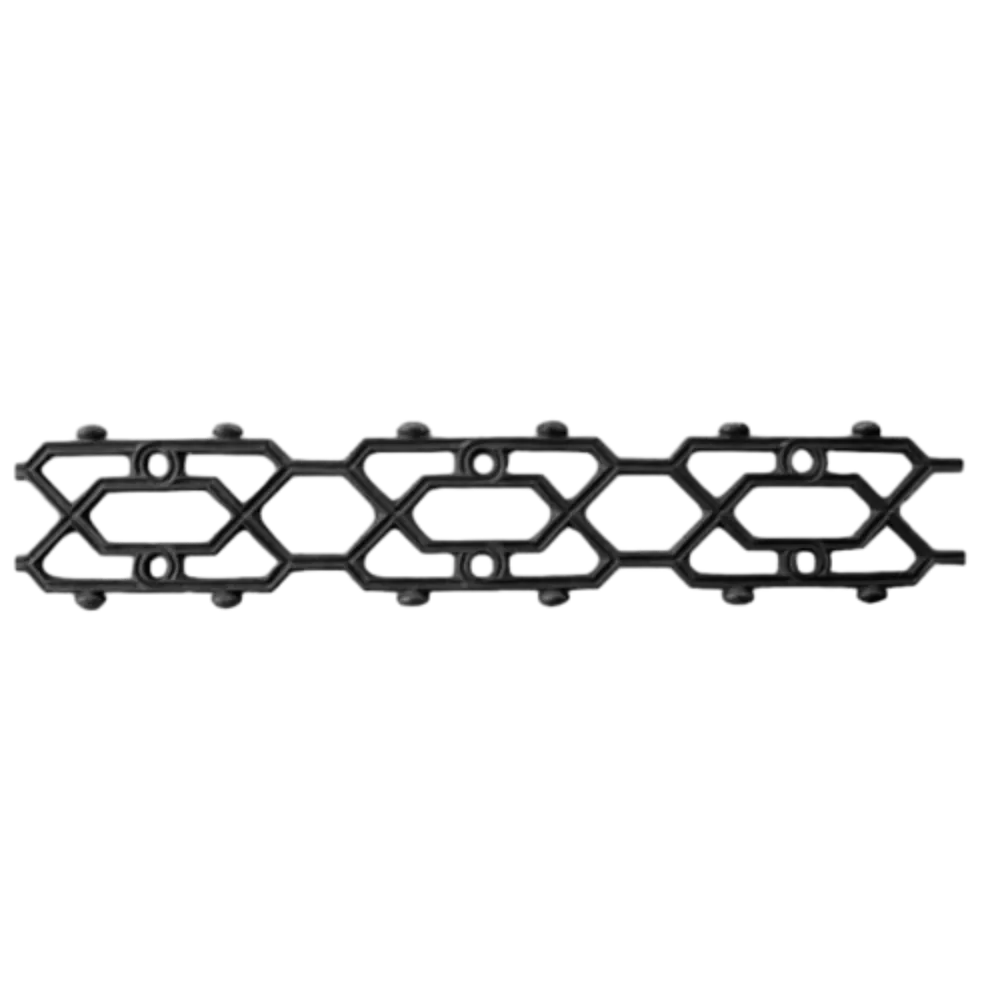

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

handle for metal door. Handles for metal doors are often equipped with features such as key locks or electronic access control systems to prevent unauthorized entry. These security features help to protect the contents of a building or facility and provide peace of mind to property owners and occupants.

In addition to their security and durability, stainless steel gate lock boxes are also very easy to install and maintain. These boxes are designed to fit neatly onto most gates, providing a seamless and professional appearance. Once installed, they require very little maintenance, giving you hassle-free security for your property.

Benefits of Aluminum Sliding Door Rollers

This rating system helps consumers choose a safe that suits their specific needs This rating system helps consumers choose a safe that suits their specific needs

This rating system helps consumers choose a safe that suits their specific needs This rating system helps consumers choose a safe that suits their specific needs steel fireproof safe.

steel fireproof safe. Residential buildings Aluminium window frame extrusions are commonly used in residential construction to provide durability, energy efficiency, and aesthetic appeal Residential buildings Aluminium window frame extrusions are commonly used in residential construction to provide durability, energy efficiency, and aesthetic appeal

Residential buildings Aluminium window frame extrusions are commonly used in residential construction to provide durability, energy efficiency, and aesthetic appeal Residential buildings Aluminium window frame extrusions are commonly used in residential construction to provide durability, energy efficiency, and aesthetic appeal aluminium window frame extrusions. They are available in a variety of styles and finishes to match any home design.

aluminium window frame extrusions. They are available in a variety of styles and finishes to match any home design. Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage

Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage Unlike baskets made of other materials, such as wicker or wood, wrought iron baskets are not susceptible to mold, mildew, or insect damage wrought iron basket. They can be easily cleaned with a damp cloth or sponge, and their durable finish ensures that they will remain looking like new for years to come.

wrought iron basket. They can be easily cleaned with a damp cloth or sponge, and their durable finish ensures that they will remain looking like new for years to come.2. Metal Wheels Made from materials like steel or aluminum, metal wheels are designed for heavier doors. They provide durability and better load-bearing capabilities, making them ideal for external sliding doors.

Plastic Taps Lightweight and Corrosion-Resistant

How to choose the right aluminium window

From lathes and milling machines to printing presses and equipment, these bases ensure precision and reliability in operation From lathes and milling machines to printing presses and equipment, these bases ensure precision and reliability in operation

From lathes and milling machines to printing presses and equipment, these bases ensure precision and reliability in operation From lathes and milling machines to printing presses and equipment, these bases ensure precision and reliability in operation cast iron base.

cast iron base.Some of the pertinent features of Type I chromic-acid anodize include the following;

Many of today’s wrought iron manufacturers add iron silicate to their product. It can be difficult to find a manufacturer that uses true 100% raw iron in their fence materials.

One of the main advantages of aluminum profile windows is their durability. Aluminum is a highly resilient material that is resistant to rust, corrosion, and weathering, making it ideal for use in windows that are exposed to the elements. This means that aluminum profile windows require minimal maintenance and have a longer lifespan compared to other types of windows.

This will help you choose the right replacement wheels This will help you choose the right replacement wheels

This will help you choose the right replacement wheels This will help you choose the right replacement wheels fixing screen door wheels.

fixing screen door wheels.We’ve explored the ins and outs of aluminum vs wrought iron fences, diving into aspects like aesthetics, durability, cost, security, and maintenance.